There has been a lot of chatter over the years about driveshafts, balancing and vibration. In general, the later Aurelias with the rubber doughnuts have less vibration; if the car is good, leave it alone. If its not, find someone who really knows what they are doing.

One of the most common errors is to try to fix “alignment issues” with balancing: if the shaft is out-of-alignment, balancing can fix some, but not all of the vibration. Alignment issues can arise from the individual pieces no longer being “straight” or axial when assembled, more common with aged fittings and slightly tweaked end couplings than one might imagine.

Here’s a draft penned some time ago, which might give some reassurance to any investigation.

Aurelia driveshafts

October 27, 2011

Preliminary

Driveshaft vibration is a sensitive topic. Due to their long driveshaft, rotating at engine speed, Aurelias are susceptible to vibration. Some cars suffer, others not at all. Do some cars have more vibration or is it just a matter of taste?

How to get rid of vibration? Vibration can be solved, but only if approached correctly. Fixing vibration means first identifying the problem – and that is often overlooked. Once the root cause has been identified and addressed, vibration can be vastly lessened.

Overall

The driveshaft in the Aurelia is directly connected to the engine and spins at engine RPM. It conveys all the engine power to the transmission and are thus critical elements of the power train. It has hard work to do, and is exposed to the elements.

Vibration is a result of two things: rotating components being out of balance is the common understanding, and thus putting them back in balance solves the problem. However, vibration also comes from rotating components (even if in balance) being out of alignment – and balancing is very limited in solving this. The solution is to get the elements back in alignment: corrective balancing is then used to take out the minor inconsistencies of the assembly, and is usually a modest affair once things are set up correctly.

Zero vibration is very hard to achieve. Even a modern car has some vibration – noted by our ability to tell if the motor is on. But todays vibration is mostly negligible. In the early 1950’s, minimizing vibration in an engine speed driveline was a challenge, as there were no ideal solutions at the time. Lancia’s work on the Aurelia represented not only the best available solution to this problem.

There were three different driveshaft designs in the Aurelia:

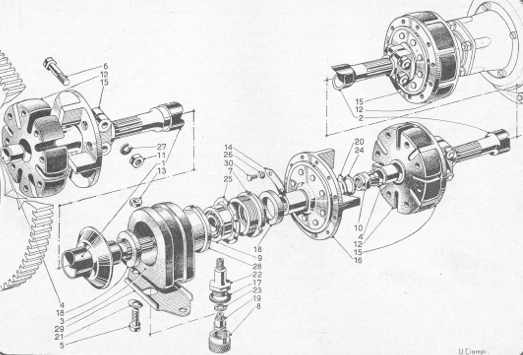

The first one (#1) was used in the s. 1 sedans, and s.1-4 B20s. It has two small shafts, with alum “fingers” that compress a rubber spider at the joints (three total). Early driveshafts came in two parts, with two similar assemblies: a shaft tube, with machined end assemblies inserted (and welded) into the tube ends. These end assemblies included aluminum “spider” holders slipped over machined spline ends. The shafts had at their ends rubber spiders, compressed between the aluminum holders, simpler to assemble than to explain.

The driveshaft is in two pieces – a front one that mounts to the flywheel, a back one attached to the transmission input shaft. There is a center housing, with a floating bearing in a rubber mounting, whose position shifts as the shaft spins up. These earlier shafts have smaller tubes and less inertia. They spin easier but are not as strong as the later larger shafts.

The s. 5 and 6 cars (B20s and B24) used a different driveshaft (#2) with a similar geometry to the earlier cars, but with hexagonal rubber doughnutsinstead of rubber spiders. Their aluminum holders were simpler, and they had larger hollow tubes for the shaftsshafts. The doughnuts are held with six bolts and easier to install - requiring less “feel” as installed than the earlier type. The rubber doughnuts were also used in Flaminias and in other makes up through the 1980’s.

One other shaft (#3) was used in the later B12, not widely known or appreciated. The B12 parts book shows two different solutions used in that car, and the later one had a single continuous shaft from the engine to the transaxle, with no joints in the middle. The shaft has rubber mountings, but not floating as in the earlier cars. This single continuous shaft is a later alternative to the adjustable coupling, and its central mountings would have reduced whirling. It is interesting that this approach was done just before they were developing the rubber doughnut solution, with this as an interim development.

Issues of the time

In short, at the time of the Aurelia (c. 1950-1957) ready answers on how to make a smooth driveshaft were not available. The evolution of the Lancia shaft is thus a brief discourse in how to solve this problem, and the evolution of their driveshafts a work in progress. That said, there is a small pleasure in a well-solved early driveshaft instead of the later ones. Of course, one alternatives might have been a single long shaft with CV joints at both ends, but CV joints of that period could not take the RPM and stresses of the motor-speed Aurelia driveshaft. Another solution would be to place the drive shaft in a torque tube bolting the transmission and engine into a solid unit. In the 1960s this was used successfully by Ferrari, but was not commonly available in the 1950s.

Splitting the driveshaft into two parts was logically done to reduce the possibility of a long shaft “whirling”, an issue solved with the two shorter and stiff shafts. Today, many trucks can be seen with shafts in two parts for this same reason.

Lancia’s central shaft mount used a flexible center coupling. Its location is fixed horizontally (in plan), but floats vertically. This allows the shaft “seek” its own alignment than fix it in place. This may have been a bit of a struggle at Lancia – one notes no data sheet on this setup. Imagine that the pure engineer (desiring the straight shaft) and the production mechanics (preferring something that self-aligns) might have quarreled on this. Reality wins: the shaft should be left loose, and seek its own center.

Comparison

How smooth is smooth? There is no clear answer to this question. Today vibration is measured more precisely. It is evaluated at different frequencies - but this is difficult to do outside of a factory and on an old car. So for these cars, vibration is sensed by experience. It is judged excessive if objectionable. So for comparison, the following were observed:

•An unrestored B24 spider was found to be very smooth. In most of the rev range, there was no feeling of engine harshness, but there was some buzziness on a small amount of the rev range. In general, the setup of the engine seemed a bit soft and low on compression, but it was all very pleasant.

•An unrestored B20 was found with some minor buzziness through the rev range, but not objectionably so. The car was not perfectly smooth throughout the rev range, and at some RPM was more buzzy than others, but without any strong vibrations. High frequency vibration was evident.

•A very original 4th s. B20 in California had been returned to the dealer after being bought new because the owner felt it had too much vibration.

Lancia folklore suggests that originally the driveshafts were smooth from the factory. If they have been monkeyed with, they are very difficult to get smooth again. So the goal often stated is to return them if possible to the factory settings. Put in new rubbers, and the bronze bushings.

Those are reasonable approaches, and in many cases, all that is needed. But if these steps are not successful, one must go deeper into the problem. For that, some theory is needed.

General Approaches

Driveshafts have many jobs to do, and must do them under difficult and exposed conditions underneath the car. They transmit power and thus are loaded for torque. This ever changing load is sometimes large, sometimes non existent. They also may be designed to cushion torque reactions, thus serving as a damper so that abrupt changes in load from engine to transmission (or in reverse) are moderated. For example, cush drives in motorcycles employ a similar rubber spider as the early Aurelia driveshafts for much the same reason, to ease the shock of abrupt loading conditions, such as a missed shift.

Driveshaft difficulties turn out to be more common in the industry than one might suspect. Late cars, such as Porche 924 and Alfa GTV-6's used shaft designs similar to the Flaminias, and repair shops have struggled with some of the same issues. While these shafts are much improved, people have found that GTV's with much increased horsepower have had difficulty with the rubber doughnuts and the shafts in general.

Some may remember the difficulty with the Lotus Elan and their rotoflex couplings in the halfshafts. Later CV joints solved that.

The most comparable experience to the Aurelia difficulty is probably with the Ferrari 275 GTB, with its transaxle design. Surprisingly, this car had three different driveshaft designs, using CV joints at both ends of the driveshaft in their intermediate design. As these did not hold up, they then went to a torque tube design, bolting the engine and transaxle into a single unit. A simple shaft ran from the motor to the transaxle inside the tube.. This solution was successful. Corvettes of the late 1990’s use the same torque tube design for its driveshaft.

Definition of Terms

Alignment, balance and vibration are key terms. Balance and alignment are often confused. Of all the issues, alignment is of most interest. Imagine a single line through the center of the crankshaft, the driveshaft, and finally, the input shaft of the transmission. While all the pieces are rotate on this line, so too should the center of the rotating masses. Any deviation causes vibration. Its that simple: the center of mass for all the pieces of the driveshaft should rotate around this single centerline, with each part’s “center of mass” at EXACTLY the same center as every other piece of the driveshaft. If this were so, one could then assemble all the pieces of the driveshaft on top of each other, spin them, and the entire assembly would spin smoothly.

While possibly true at the time of manufacturing (and today with higher precision in manufacturing) this is not likely in reality: not all pieces will have exactly the same center of mass; machining differences can cause slight irregularities in the fitting of one piece to another. Over the length of a driveshaft, small angular irregularities in the fit add up as minor, but significant, out-of round driveshafts. Thus, after assembling these “out of round” components, one typically balances to correct for these slight mis-alignments and "off centering".

To do this best, driveshafts should be balanced as assemblies. Component balancing, while much more convenient, will do little to correct this. The exception to this is for large assemblies, such as flywheels or clutches, which if out of balance can cause significant vibration.

In the 1950s, Lancia aligned and balanced their shafts as entireties. But that was sixty years ago,with fresh components. Consider the following for the earlier driveshafts:

•Shaft ends and spline fittings - the accuracy and precision of the spline fit is important to hold the driveshaft in true alignment. Spline design is a tradeoff between smaller and more precise splines (more costly) vs. larger spline sections with easier manufacturing. Lancia shafts are good with a large number of splines. Lancia spent their money (typically) on good machining. On the other hand, comparison to a later Alfa GTV-6 shaft shows progress in the later Alfa: the diameter of the spline coupling is about 1 3/4" on the Alfa, vs. 1" on the older Lancia. So with fewer number of overall splines , the Lancia splines are subject to more wear.

•Centering bushings and pins - multi-piece driveshafts need some means to center the various pieces of the shaft. The Lancia shaft works on centering pins with a precision fit through some bronze bushings. As these bushings wear, they need to be replaced. Slight gap in the bushings can result in loose fit, and produce resultant vibration. So too, over time, the steel fitting into the bushing wears as well.

•Center bearing – this helps locate the driveshaft, and cut down the shaft’s unsupported length, lessening likelihood of driveshaft resonance or “whirling”. This center bearing need both to float and be supported, so it is mounted in rubber and a sliding rubber C-shaped mount. Today's manufacturers mount the bearing in a rubber casing, with rubber spanning the 1/2 - 1" distance to an outside, solidly mounted, metal casing. A driveshaft can work well with one of these new center bearings mount yet vibrate with another type, suggesting these are tuned by manufacturer to their driveshaft.

Balance

One daunting aspect of balancing Aurelia shafts is finding individuals with the temperament to deal with its assembly. A well balanced shaft is best tested so as to replicate its the real world use. Its assembly on a balancing machine should include mimicry of the car’s fixture conditions at both ends. Thus, special fittings for mounting at both ends are needed.

There are ways to balance the driveshaft in the car. Years ago there was a Lanciana article on how to make your own home-grown transponder, to make a testing apparatus to do "in car" balancing. Some people try the “guess and by golly” to make a shaft balanced, but these have limited success. However, with enough patience, shafts can be smoothed out with this technique. This has been replaced with some sophisticated balancing arrangements some of whom are using state of the art equipment to do this. All of these assume the balancing problems are minor. If not, then this approach will not likely yield a good result.

Repairing a driveshaft

Roger Vrilikas at Driveline Service of Portland is highly recommended. He has worked on a few Aurelia shafts for me with good success. He has both theoretical and practical knowledge of driveshafts – and he is familiar with Alfa GTV6’s. The shop also does big marine shafts. (FYI - there are other operations, including a man in Holland, which appear to have a good understanding of these issues as well, but I have not dealt with them).

Roger’s shop first inspects the shafts, and finds issues – mostly alignment. They examine each part, making sure it was straight and true. In my shafts, the fitting splines they were kicked slightly out off true, as the connection of the spline (into the tubes) had given a bit over the years due to wear. They heated the ends of the tubes, and gently pushed the splined bits into alignment, back on axis. So too, by fiddling and switching the paddles for the spiders, they were able to get the entire driveshaft to spin much more straight. They also made end couplings for mounting the shaft, and were able to get the runout down from .020” to .006”, measured along the whole shaft, not just at one place. Once straight, balancing the shaft was very simple. In short, its alignment first, then balancing.

Using balancing to take out alignment-induced vibration is not ideal, although possible in minor instances. When alignment issues become severe, correcting this by adjusting balancing is limited. Better to address the issue at the source.

Installation is critical on the early shafts: the center bearing must be mounted so that the shaft starts low (drooping below the center line). The center bearing needs to be set up about 3-5 mm down from straight, so that the shaft has a slight "downwards" kink when resting. As the shaft spins up, this allows the shaft to move upwards and establish its alignment. A proper amount of compression should be maintained on the rubber spiders between the two alum clamping pieces – typically this is reached with 1/8” clearance between the two alum clamps. Overall, an installation of an early driveshaft is pretty straightforward. A correctly aligned shaft was re-installed in a B20 and spun like new and worked fine. No issues – no buzziness, no rumbles. Just a smooth sweet car from the 1950’s.

This should be put in perspective – this is smooth per 1955, not 2012. Even as a well aligned and balanced shaft will spin cleanly and smoothly, there will still be a background “whirring” noise. Its like an old machine shop, with the lathes in the background. Its not overt, but there is a clear background presence. At idle, if the throttle is purposely blipped, there can be a bit of sideways rumbling and even a rare thump. Most of the time, it just works fine.

Later B20’s and B24’s with the second shaft type are smoother– the vibration is more dampened, and more isolated. The shaft is hardly noticeable – so much smoother, but not as much fun! In these driveshafts with rubber doughnuts, out-of-alignment force is collected in the hexagonal doughnuts. These twist and absorb movement as the shaft spins up, until there is sufficient energy to move the shaft to better alignment. Thus, at very low RPM, a rumbling from the driveshaft may be experienced until things smooth out ( say 1200-2500 rpm). This is true on the Alfa GTV-6 driveshaft of similar design, suggesting there wasn’t a better way twenty five years later.

Other Vibrations

Roughness from the running engine may exist and be felt as vibration. In most Lancias, the engines are understressed, and so this is not a cause of vibration. However, if all else fails, it is worth considering this possibility. To distinguish engine related vibration from the driveshaft, . check by disconnecting the driveshaft and running the engine. Motor mounts vary in hardness - original mounts were very soft, replaced by Flavia mounts and later remanufactured ones were harder. In general, mounting rubbers have not been seen as critical.

Far more important are the mount isolators from the motor to the car, which if not assembled correctly, will transmit engine vibration. Aurelia motor mounts on have a larger upper rubber mount in a steel cup, welded to the car. There is a smaller rubber mount underneath. A steel sleeve that goes through both mounts, and is held from below with a large steel washer plate and a bolt into the engine mounts. This sleeve was never to touch the car rather it was held off by the two rubber mounts. The torque on the mounting bolt (18 ft lbs. ) simply is the tension of the bolt directly on the sleeve, but the compression level on the rubber mounts is determined by the length of the steel sleeve itself. Replacement sleeves need to be carefully trimmed to the right length.

Also check engine placement in the car: if the car has been hit, the engine mounts can be distorted and the engine pushed out of alignment. While there are drawings for the precise locations of the engine mounts, actual measurement is difficult. Construct a line from the center of the crankshaft in the motor to the transaxle by placing a laser pointer into an empty crankshaft journal to shine along the crank center axis; spot this on the transaxle to check for alignment. Surprisingly, in one car this was off by 5”, evidencing relocated engine mounts. Once corrected, it was much better. Although not common, it is possible.

Conclusion

Most balancing issues are a result of alignment. Check each of the components, and try to get the shaft straight as possible before balancing. Use out of the car balancing if possible, carefully replicating the end mounting conditions. Install carefully, respecting the floating mount of the earlier center bearing. Adjust in car by carefully rotating fittings on a trial and error basis. If all else fails, consider in-car balancing software, and look for other issues on the car.

1. getting vibration out is time consuming, takes diligence and meticulous work.

2.if the car has an original driveshaft in place and is running smoothly, leave it be.

3.If there are vibration issues, isolate the cause – first, engine or shaft? If shaft, make sure its truly straight, all from one end to another.

4.Balancing pieces alone will often not solve the problem – the whole has to be addressed.

Good luck!

Note: a couple of years ago, I visited Beppe Regazzoni in Italy, former head of the Registro and a longtime Aurelia owner (for over 50 years). He carefully maintains his own driveshafts. The ride in his B50 was amazing - there was no driveshaft sense at all - amazingly perfect. So it can be done, but it takes time and care.