Technical Tips for today’s Aurelia

ENGINE

Rocker shafts sometimes show a great deal of wear. Walt Spak in Pittsburgh has had luck in getting these sprayed and re-machined to original tolerances.

Pushrods are of different lengths: If you change lifters on an earlier car, shorten the pushrods about 1/8”.

Flywheel weights vary but are typically stock around 19#. It can be reasonably lightened to 15#, which gave smoother shifts (from better alignment) in a 6th s. B24. Flywheels on early 2 liter cars do not need lightening. Sergio Allais makes a very very light competition flywheel, if so inclined.

Early conrods are delicate looking, but gorgeous. Later ones are robust. Aurelia bottom ends, especially shell bearings, are very solid.

CRANKSHAFTS

Unlike conventional crankshafts, the Aurelia crank (and subsequent V-6 engines) is designed to be balanced with bobweights., and it must be spun with associated weights added, to approximate the con rods and pistons. This is now conventional wisdom, but if you change piston weights, you will need to rebalance the crank.

PISTONS

These are remade in Italy, or in the US - J&E pistons from California have made pistons for 2 and 2.5 liter motors. For the larger motor, order # JE 423 639 will give (in a redone 2.5 liter engine) about 9:1 CR, after removing about .020" from the heads. This piston is a slight overbore as well. With a more standard setup, it would be around 8.9:1 CR. Their remade 2 liter pistons were done with the standard compression, but modern ring sets.

CAMSHAFTS

Cams have been remade in Italy - typically to a s. 4 B20 profile in both the early and later sizes. Early B10 cams have also been remade, as well as some adaptations of Nardi setups. The best high-performance setup in the US comes from Megacycle, their 90199 cam - if they will still make it. Dema of Elgin Cams made a wonderful cam for me, but I don’t know if he’s still making cams. Additional documentation on camshafts is published on this website at What Cam to Use.

CARBURETORS AND FUEL

Generally, people feel that performance gains with the Nardi setup are not worth the tradeoff in usability. However, this has a lot to do with how the engine is set up, which cam is used, and the overall condition of the carburetors. A well-setup Nardi carb kit can pull from idle and give a level of zest that the stock carburetor cannot. On the other hand, Tim Burrett has been racing in Europe for years successfully with an enlarged single 2 barrel carb, with simplicity of installation and good performance.

Check the jet sizes by measurement, as over time, some have been reamed and are no longer accurate. For carb rebuilding (and the all-important butterfly shaft rebushing), go to Pierce Manifold in California.

Nardi made several different air cleaners for Aurelias in the 1950’s, typically in cast alum with a wire mesh screen: the most common was made for the 2.5 liter B20 (although with three different types of labelling), and these work on the B24 Spider. Curiously, the air cleaner for the B24 Convertible, was yet again different (lower and wider). Cavalitto has remade air cleaners in sheet metal and cast as well.

To cure vaporlock and ease cold starting, fit an electric pump (preferably back by tank where it won’t be seen). Hide a switch under the dash.

To cure hot starting issues, especially in hot summer heat and with a Nardi kit, consider fitting a fuel return line (see Fulvias, for example). This takes expanded and hot gasoline back to the fuel tank, rather than it pushing past the carburetor jets and flooding the car. It makes very hot starts easy again.

COOLING

Peter Harding notes that the radiator caps on early Aurelias (B20 s. 1-4) were not pressurized, s. 5-6 were - at 1/2 bar, or with 7 psi caps.

Thermostats - some remade ones flow differently than original older types; Classic Tuning (Netherlands) has remade the original type in bronze. They look good, but have not yet been tested.

FUEL PUMP

Check the pressure coming off the mechanical pump - it should be between 2.5 and 4 psi. The pump is extremely sensitive to rod length and shimming. Too much pressure will quite likely push fuel through the carbs and can wash out cylinder bores.

ELECTRONIC IGNITION

Crane’s Fireball XR700-023 (www.cranecams.com) makes an optical trigger that fits well, gives better starting, and better top end as well. One little wire from the distributor to a box hidden below the dash. If necessary, the points can be readily re-installed at a later date. Make sure you have a good rotor and cap tho.

TRANSMISSION

Curiously, the earlier cars had all the same transmission, but not quite. It turns out that from the 1st to the 4th series, three (!) different third gears were used. The first was originally used in the B10, then there was a fix that starts around the middle of the first series B20, and then another change in the middle of the fourth series.

First gear clusters have been remade and can be found in Italy.

Consider changing the hydraulic clutch in the later cars to a manual clutch from the earlier cars. This requires changing some parts of the pedal box as well as the clutch release rod off the transmission, but long-term worries of hydraulic failure are over.

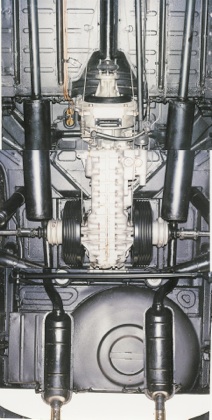

DRIVE SHAFT

Balancing the driveshaft takes time. For the earlier cars (s. 1-4), it takes patience too. A process is well described in the LMC manual. I’ve also had good luck with Driveline of Portland (Roger Vrilikas). They take the time to align all the pieces to very tight centerlines, and then balance the whole shaft. They found that the splines in the early driveshaft get a wee bit cocked, and the aluminum paddles get a bit out of perpendicularity - so they heat up the ends of the shafts and re-aligned the splined ends.

Also, as a last resort, check the alignment of the engine centerline (along the crankshaft axis) to the center of the transmission input. They should be straight in line with each other. If the car has had an accident, or the motor mounts moved, they can be out of alignment.

SUSPENSION

By now, it is worthwhile rebuilding the entire suspension on your Aurelia. The front is a complicated assembly and needs a specialist.

In the rear, it is useful to take the leaf springs apart, clean them, and replace the rubber interleaving (avail. from Omicron). There will be reduced stiction and a more supple ride will be found.

Take care to reinforce the suspension mounting points, including front and rear, and especially at rear leaf spring mounts. Over the years, these attachments have weakened, and they should be rewelded.

BRAKES

To avoid the shimmy common to Aurelias, all the suspension bits must be in good order. Brake drums need to be balanced as well. Some cut the drums to accept the shoes without shimmy, but Tony Nicosia nows grinds them - to take less off and get a better fit.

Some of the different series B20’s have different brake drums. I just learned that the brake drums (and shoes) for the s. 2 B20 are in fact wider than in the B12 (which is a later car) .

WHEELS

The two basic wheel types are the rolled rim (earlier type) and the later stamped rim (easier). Bill Stebbins has documented the varied different rolled rims (no, there is not just one!).

Borrani made wire wheels (unattractive), aluminum wheels with steel hubs (neat, very rare!) and even steel wheels for Aurelias. The early Lancia steel wheels with the rolled rims weigh about 18# apiece. The steel Borranis, with a better rim profile, are not any lighter.

Tires (Michelin 165x400 X) can be found from Coker Tire in the US. Order tubes as well.

BODY - PAINT COLORS

Original paint colors are reasonably known, but there are always exceptions. Lechler has reissued these paint colors with modern paint numbers (but they are only available in Europe). Paint wheels are very scarce. Best is to find a piece of the original paint somewhere on the car and match it.

BODY - CHROME

Current chrome is done to meet environmental standards, and tends to have a brightness, or bluish quality to it that takes away from the character of the cars. It is possible, by fiddling with the chroming process, to get the more yellowish chrome color of the older car, but very hard to find people who will do that.

INTERIOR

Cloth or leather. Hirsch (in the US) supplies very good English wool in many colors. Trinchero has remade the grey and nocciolo (dark hazelnut brown) cloth for older cars as well.

Use Italian vinyl where possible, as it thinner and holds the lines better in the installation. Keep the welting very thin, to match original.

Cicognani has remade weatherstripping and the interior rubber mats for the cars. They used the original molds, but the rubber mats are a bit thicker. Not any real options there. The weatherstripping is decent, but not great. At one time, Bob WIlliams in Pittsburgh had made new weatherstipping molds for his restorations. Re-Originals, or Mike Kristick can help here.

Cloth interior looks great - headliners now have to be made of the same material as the seats - the original cars had a lighter weight cloth which is not findable today in the colors used in these cars. Cloth sun visors are tricky to make.

WINDSCREENS

Omicron has remade a number of the windscreens in England. The quality is good, and they fit. Omicron packs them well for shipping.

A company in Finland is also making windscreens, but I have no experience with them. (see Viva Lancia forums for contact information).

INSTRUMENTS

In the US, Palo Alto Speedometer does good work in restoring instruments. Best to make one’s own cables, as getting the right length and fittings from overseas is a bit like gambling, but you rarely win.

PARTS BOOKS AND FACTORY DATA

There are two different parts books for the Aurelia - the first series covers up to 1954 (3rd s. B20) and the second series has the B12 and the later cars.

There are typically three different books used - a very early (c. 1951) s. 1 parts book, the later s. 1 parts book of 1954, and then the late s. 2 parts book of 1959.

Depending on which model you have, you have to use the appropriate parts book. The page numbers on these books are NOT identical - the later one is one tav off from the earlier one.

DATA SHEETS

There was no factory manual, but many factory data sheets are assembled in Paul Mayo’s Aurelia Manual. James Steerman has published most all the data sheets in a separate book, thankfully!

Information for Aurelias includes:

-

1) Workshop Manual

-

2) Parts books, and owners manuals

-

3) community of people

Take a look on this site for “the Web” for links to the resources.

WORKSHOP MANUAL

There was never a factory workshop manual. However, over the years, the English Lancia Motor Club put together a workshop manual carefully tended by (and available from) Paul Mayo. Extremely well organized, it is a combination of factory data sheets and individual experiences over some 40 years. Order from: lancialib@onetel.com

PARTS BOOKS AND OWNERS MANUALS

These are available on CD from Huib (www.vivalancia). Any Aurelia owner should have these, the bibles for an Aurelia - immensely detailed, and quite accurate.

COMMUNITY

Knowledgeable people exist in the clubs. The US club is small but everyone knows each other. There is also an amazing knowledge base in Europe, especially in England, Australia, and of course, Italy. Join the clubs! The English run an active web site as does VivaLancia.com.

James Steerman republished many of the factory data sheets, an immense help. Also try the Viva Lancia forums to post questions.

TECHNICAL NOTES

PARTS SOURCES

SUPPLIERS

Parts for Aurelias are reasonably available. Small trim bits are very hard to find, while running parts (mechanical) are generally available. Sources include:

Mike Kristick, in the US (717) 292-2962. He’s honest, modestly priced, and fair. Note this is not a major retail operation, just Mike on his own.

Omicron in England is a leading Lancia commercial operation, and Elizabeth Cliffe handles the parts. She knows a good deal and I have had good luck with them.

Cavalitto in Italy has most all the parts, but shipping is not their best look. Mike Kristick imports parts from them.

There are other smaller vendors that sometimes have parts, but these are the main sources.